pressure sensitive adhesives tack test

Rolling Ball Tack Tester

ASTM D3121 & PSTC 6 & JIS Z0237

About

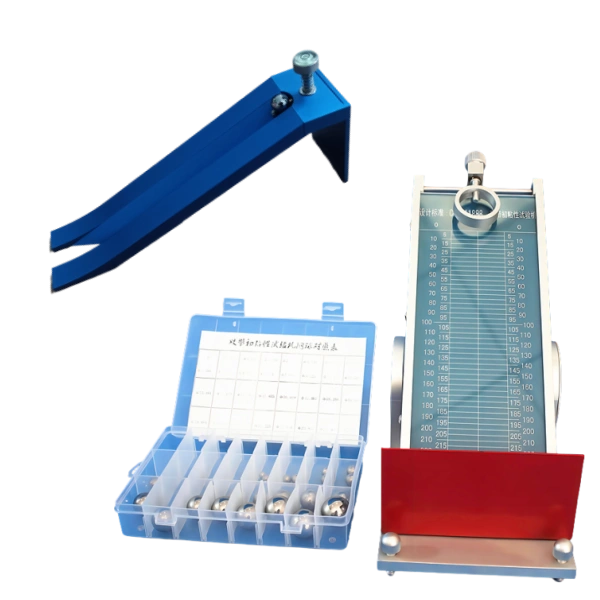

Rolling Ball Tack Tester

Rolling ball tack tester is a specialized instrument designed to measure the tackiness of pressure-sensitive adhesives using a standardized ball tack test method. The core principle involves releasing a stainless steel ball of specified diameter down an inclined ramp onto a horizontal strip of the adhesive tape sample. The distance the ball travels on the adhesive surface before stopping is measured. A shorter distance indicates higher tack, as the adhesive more effectively halts the ball’s motion.

This tack rolling ball method is celebrated for its speed and reproducibility, making it an invaluable tool for quality control in adhesive manufacturing and application. The apparatus itself is relatively compact and straightforward, typically consisting of an inclined trough with a release mechanism, a leveling base, and a set of precision-calibrated steel balls.

rolling ball tack tester

What is Rolling Ball Tack Test Method?

Rolling ball tack refers to the ability of an adhesive to form a bond with the surface of another material upon brief contact under virtually no pressure.

The term rolling ball tack refers to a simple and effective test that measures the initial stickiness of a pressure-sensitive adhesive when it first comes into contact with a surface. Unlike peel or shear strength tests, this method specifically evaluates how quickly an adhesive can “grab” an object under minimal pressure.

In practice, a steel ball is released down an inclined plane and allowed to roll onto a strip of adhesive tape. The shorter the distance the ball travels before stopping, the higher the tack of the adhesive. This method is especially useful for quick quality control checks in adhesive tape production and packaging applications.

ASTM D3121 & PSTC 6 & JIS Z0237

Standard Test Methods for Rolling Ball Tack

To ensure consistency, rolling ball tack is described in several international standards. The most widely recognized include:

01

ASTM D3121 – Standard Test Method

ASTM D3121 is a global benchmark for evaluating the tack of pressure-sensitive adhesives by rolling ball. It specifies:

- A steel ball of 7/16 inch (11 mm) diameter.

- Inclined trough with controlled angle.

- The requirement of multiple replicates (at least five per lot).

It is best suited for low-tack adhesives and is primarily used in quality control, not for final product specification.

02

PSTC 6 – Tack Rolling Ball

Issued by the Pressure Sensitive Tape Council, PSTC 6 defines rolling ball tack as a measure of the ability of an adhesive to form a bond upon brief contact under virtually no pressure. It specifies sample dimensions (24 mm × 375 mm tape) and emphasizes the importance of cleaning the ball and raceway with solvents like isopropyl alcohol before each test.

03

JIS Z0237 – Japanese Standard

JIS Z0237 provides procedures similar to PSTC and ASTM but includes additional parameters to adapt the rolling ball tack test method to Japanese adhesive tape industry practices. It emphasizes control of adhesive film thickness and backing rigidity, which strongly influence results.

By following these standards, laboratories and manufacturers can ensure their rolling ball tack testing is accurate, repeatable, and comparable across global markets.

rolling ball tack tester price

Choosing the Right Rolling Ball Tack Tester

When selecting a ball tack tester, key factors include the adjustable incline angle, trough length, ball size options, and ease of specimen mounting. A high-quality instrument ensures repeatable results while minimizing operator error.

Cell Instruments offers two professional-grade solutions:

01

BTT-01 Rolling Ball Tack Tester

Compact and lightweight, with a fixed incline angle of 21.3° and a 7/16-inch steel ball. Ideal for routine quality control.

02

BTT-02 Rolling Ball Tack Tester

Versatile with adjustable incline (0–60°), wider test area, and multiple ball size options. Suitable for research laboratories and adhesive development.

Both models are designed according to PSTC 6, ASTM D3121, and JIS Z0237, making them compliant with international adhesive testing standards. By choosing Cell Instruments’ rolling ball tack tester, manufacturers can achieve reliable, accurate, and repeatable results across production batches.

ball tack test method

Rolling Ball Tack Test Method Explained

This rolling ball tack test method is valued for being quick, economical, and highly reproducible when performed under controlled conditions.

- Preparation of Specimen – Adhesive tape is cut to standard size (commonly 24 mm × 375 mm) and placed adhesive-side up on a clean, flat horizontal surface.

- Cleaning – The steel ball and raceway are cleaned with recommended solvents (e.g., MEK, acetone, or isopropyl alcohol) before each roll to eliminate residue.

- Ball Release – The steel ball is placed on the inclined trough and released, rolling down to make contact with the adhesive.

- Distance Measurement – The distance from the point of first contact to where the ball stops is recorded. Shorter distances indicate higher tack.

- Repetition – At least five measurements are taken for each sample to ensure accuracy and repeatability.

Applications of Rolling Ball Tack Testing

Rolling ball tack testing is widely applied in:

"Carton sealing tapes, protective films, and labels."

– Packaging industry

"Adhesive bandages and surgical tapes."

– Medical devices

"Protective films and component assembly adhesives."

– Electronics

"Pressure-sensitive coatings on fabrics."

– Textiles

"For manufacturers and quality inspection professionals seeking a precise and cost-effective solution, the Cell Instruments BTT rolling ball tack tester offers robust design, international standard compliance, and dependable accuracy."

– Cell Instruments

Frequently Asked Questions aboutRolling Ball Tack Testing

1. What does rolling ball tack measure?

It measures the initial stickiness or “quick grab” of an adhesive when first contacted by a surface, evaluated by the distance a steel ball travels before stopping.

2. Which standards define the rolling ball tack test method?

The test is defined in PSTC 6, ASTM D3121, and JIS Z0237, all of which provide procedures for accurate and repeatable results.

3. How is the rolling ball tack tester cleaned before use?

The trough and ball must be cleaned with solvents like MEK, acetone, or isopropyl alcohol to remove residues and prevent result variation.

4. Can rolling ball tack results predict end-use adhesive performance?

Not directly. Rolling ball tack is best for quality control and batch consistency, but it does not always correlate with end-use application requirements.

5. Why choose Cell Instruments’ BTT tester?

The BTT series is designed according to global standards, offers reliable performance, and provides both compact and versatile models for different user needs.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985